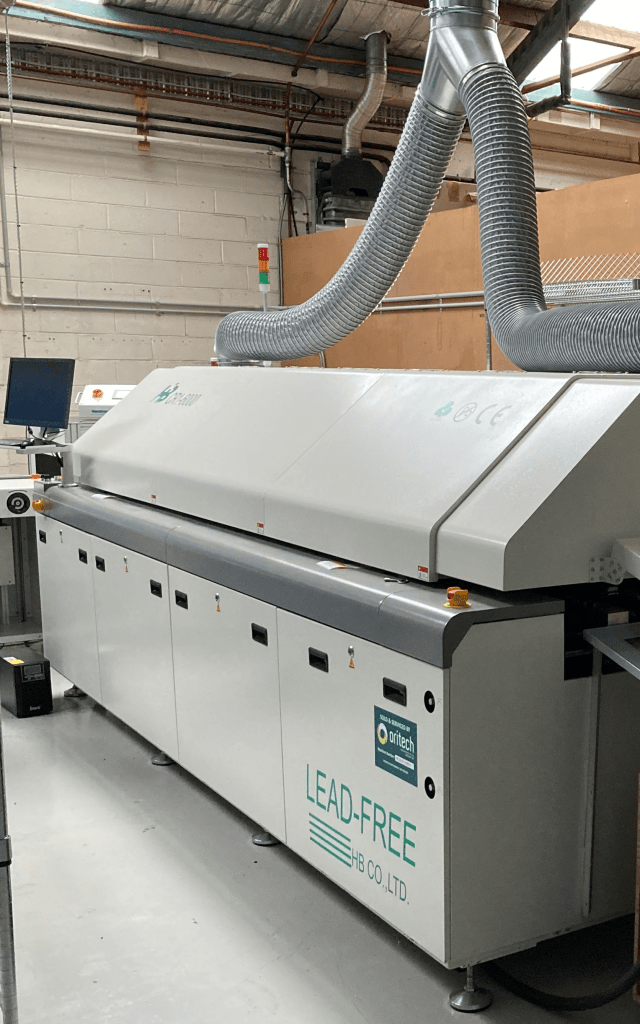

We’ve been pleased to see PCB surface mount assembly customers moving away from supplying cut tape, partly in thanks to our popular article on why cut tape is a bad idea. However, we’ve noticed a trend in recent months, where partial reels suffer a similar problem to cut tape.

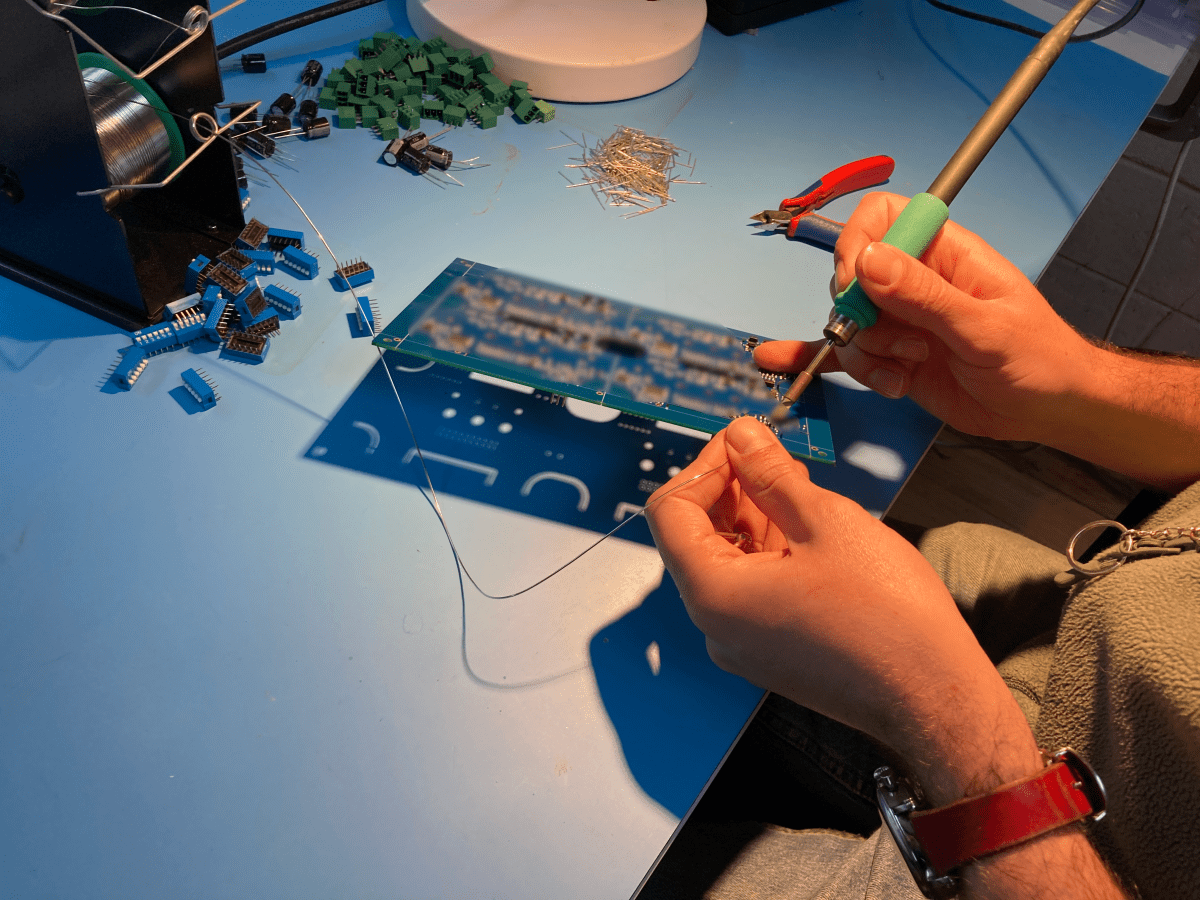

A few recent supplies of reeled parts have come on multiple reels, with some reels containing only a single component! There is no point in trying to load a reel with fewer than five components on it onto a pick and place machine (unless the component is large and expensive). Each time a reel is loaded into a feeder and put into position, there is a chance of losing a component or two, despite the care taken by the operator. This is why some assemblers insist on receiving many more parts than required for the boards. (I’ve seen 100 quoted on one assembler’s website.)

While having multiple partial reels is less annoying and costly for assembly than multiple pieces of cut tape, and will lose fewer parts, it will still lead to more parts potentially being lost or unable to be used. It will also mean multiple feeder loadings per component, which will add a few minutes per reel change to the job.

I don’t know what it costs the component wholesaler to put a single component on a reel, given that customers pay a standard fee for reeling, regardless of how many reels are delivered, but I expect that the economics aren’t really there for cheap components. While I sympathise with the goal of avoiding the waste of components, there is waste in the form of extra reels and leader tape, plus time either of workers and/or machines to create the extra reels, not to mention the additional cost downstream during assembly for customers, with components not being used. I hope this trend goes away soon. Meanwhile, I can only advise customers to choose between having fewer boards fully assembled, buying more parts, or using a supplier who doesn’t split ordered components across multiple partial reels.