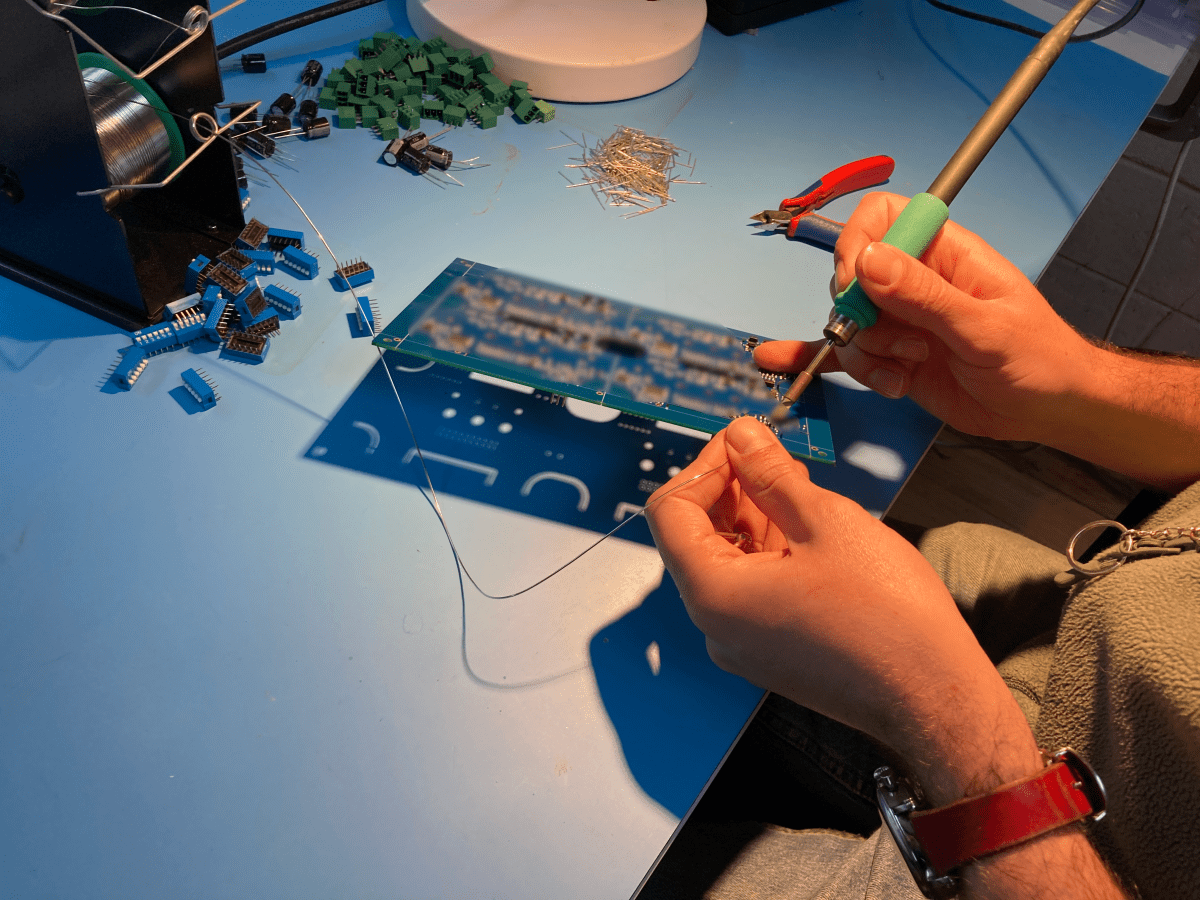

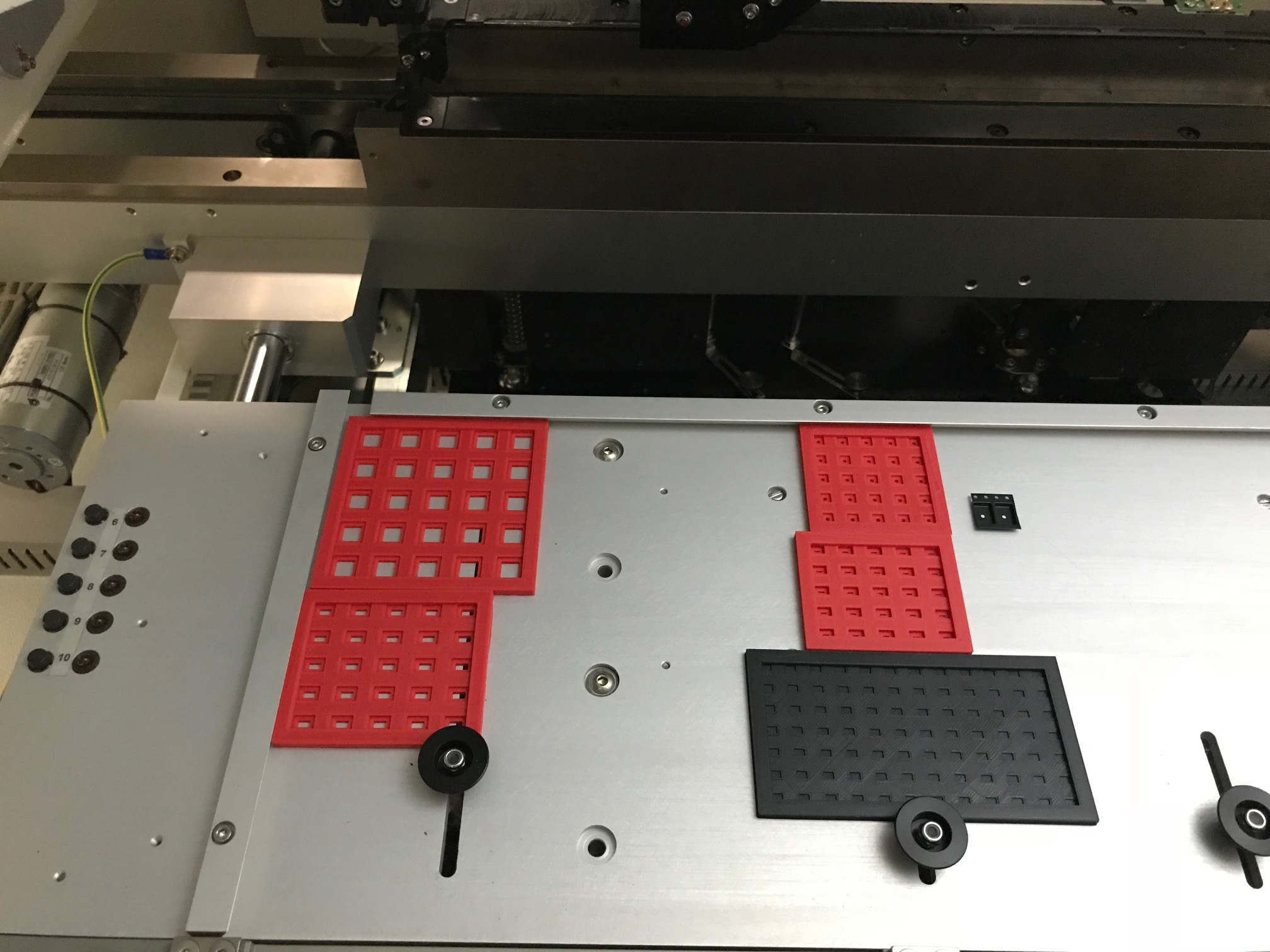

This year we’ve reached another milestone for Agile Electronics. Previously we’ve only had a maximum of two people working on electronics assembly at any one time, and that second person has been me (Sandra) since December 2020. This year, we’ve welcomed Hank to be a new casual employee, whose main role is to take on the manual through-hole soldering of boards for our customers. So this week, we’ve had Hank busy soldering and testing boards for one customer, while I was looking after the machines doing surface mount assembly for another customer, and while John inspected boards, supervised everything and helped out where needed.

With our new employee, we will be able to take on more manual soldering, so if this is something your product needs, contact us for a quote.