The next episode in our series on getting the best value out of your surface mount assembler is panelising. The surface mount assembly process involves three main steps for each board (or panel):

- solder pasting

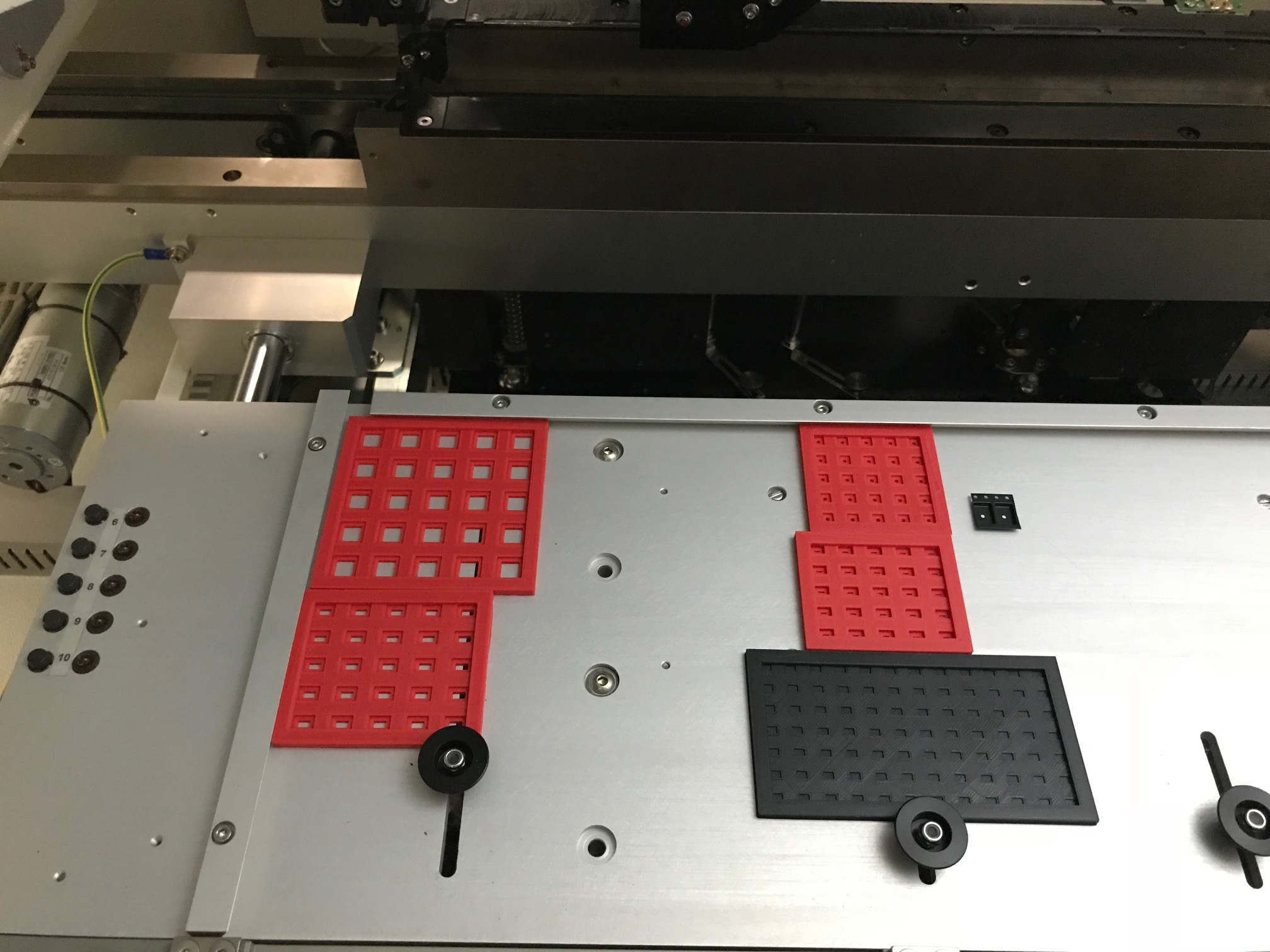

- placing surface mount components on the board using the pick and place machine

- melting the solder in a reflow oven

Each of these stages is faster if you have the maximum number of boards possible within a single panel. Suppose it is possible to have ten boards in a single panel. That can make solder pasting ten times faster.

Some gains are also possible with the pick and place machine stage, if a board takes less than a minute to populate, there could be a delay between putting it into the machine and moving to the reflow stage. The pick and place machine itself will place components more efficiently if populating an entire panel of boards instead of individual boards, since there will be fewer nozzle changes needed.

Depending on the reflow set-up, panelisation can make things much faster or just a little. If the reflow oven is automated, taking boards that exit the pick and place machine, the speed increase may be a multiple of one dimension of the panelised board. For ovens with manual input, panelisation will greatly reduce the handling required. Imagine the relative effort of carefully placing 10 boards in an oven versus one. The operator needs to be careful to avoid touching the solder paste, as well as making sure that the board is level and not jerked about, or components will be dislodged. It’s a bit like a waiter bringing a full bowl of soup to a diner.

Panelising may also provide savings at later stages, for example, if the boards need to be cleaned, then this will be faster if an entire panel can be cleaned at once.

In some cases, a board must be panelised, for example, if it is too small to be populated by the machine. The Europlacer XPii requires the board to be at least 50mm by 50mm. It must also have two parallel sides with 5mm clearance to allow it to be held by the machine.

Not all manufacturers work the same way. The degree of automation will differ. Pick and place machines vary in their capabilities. So the exact savings will differ. But as a very rough guide, if your board is very small, has an unusual shape, or you need at least 40 boards and can fit at least 4 boards in a panel, it is likely to be worth panelising.